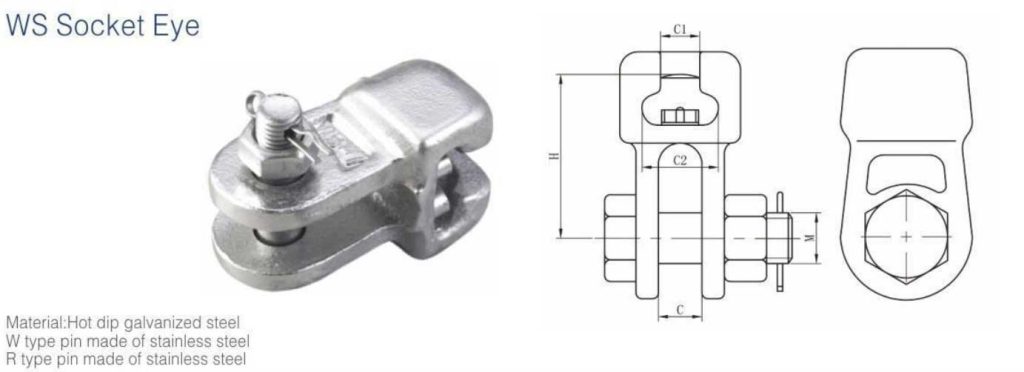

WS Socket Eye

Temperature Range: Capable of operating effectively in a wide temperature range, from -50°C to +200°C, making it suitable for diverse climates.

UV Resistance: The galvanized coating offers additional protection against degradation from ultraviolet radiation, ensuring long-term outdoor use.

Chemical Resistance: Resistant to common environmental chemicals, maintaining the bolt’s integrity in various conditions.

Humidity Tolerance: Engineered to perform well in high humidity environments, preventing rust and corrosion.

Share:

Product Description

Product Introduction:

The WS Socket Eye Bolts are engineered fasteners designed for high-strength connections in various industrial applications. Characterized by a socket eye and a threaded bolt, these bolts offer versatility and reliability under load, making them ideal for securing and suspending heavy equipment.

Product Details:

- Material: Constructed from hot dip galvanized steel, ensuring exceptional durability and corrosion resistance.

- Design: Features a socket eye for easy attachment of cables, ropes, or chains, combined with a threaded shaft for secure fastening.

- Application: Suitable for a wide range of applications, including heavy machinery, construction, automotive, and marine industries.

Structural Features:

- Hot Dip Galvanized Finish: Provides a thick, protective coating of zinc to prevent rust and extend service life.

- Robust Eye Design: The socket eye is designed for high tensile strength, allowing it to withstand substantial loads without failure.

- Threaded Shaft: The bolt’s threaded section ensures a firm grip in a variety of materials, including wood, metal, and concrete.

Installation Process:

- Selection: Choose the appropriate WS Socket Eye Bolt based on the load requirements and material specifications.

- Alignment: Position the bolt in the desired location, ensuring the eye is correctly aligned for attachment.

- Tightening: Secure the bolt using a wrench or other suitable tool, tightening to the recommended torque.

- Verification: Confirm that the bolt is properly tightened and the eye is securely fastened to prevent slippage.

Applicable Environmental Conditions:

- Temperature Range: Capable of operating effectively in a wide temperature range, from -50°C to +200°C, making it suitable for diverse climates.

- UV Resistance: The galvanized coating offers additional protection against degradation from ultraviolet radiation, ensuring long-term outdoor use.

- Chemical Resistance: Resistant to common environmental chemicals, maintaining the bolt’s integrity in various conditions.

- Humidity Tolerance: Engineered to perform well in high humidity environments, preventing rust and corrosion.

Specifications

| Type | Dimension(mm) | Link Marker | Failure Load(KN) | ||||

|---|---|---|---|---|---|---|---|

| C | C1 | C2 | M | H | |||

| WS-7 | 20 | 19.2 | 34.5 | 16 | 70 | 16 | 70 |

| WS-10 | 20 | 19.2 | 34.5 | 18 | 85 | 16 | 100 |

| WS-12 | 24 | 19.2 | 34.5 | 22 | 85 | 16 | 120 |

| WS-16 | 26 | 23 | 42.5 | 24 | 95 | 20 | 160 |

Product Advantages

- 1. Structural Integrity: Made from malleable iron or casting steel and often hot-dip galvanized, WS Socket Eyes offer robust structural integrity, ensuring they can withstand the demands of heavy-duty electrical systems.

- 2. Corrosion Resistance: The hot-dip galvanizing process provides a protective coating against rust and other forms of corrosion, making the WS Socket Eye suitable for outdoor use in various weather conditions.

- 3. Versatility: Available in different sizes and designs, WS Socket Eyes can be used in a wide range of electrical systems, accommodating various types of insulators and load requirements.

- 4. Ease of Installation: Their design typically allows for straightforward installation and maintenance, reducing the time and complexity involved in electrical infrastructure setup.

- 5. High Load Capacity: Designed to handle significant loads, WS Socket Eyes are crucial for supporting heavy insulators and ensuring the stability of overhead lines.

Application Places

The WS Socket Eye has various applications primarily associated with overhead transmission lines and electrical infrastructure. Here are some applications:

- Support for Insulators: WS Socket Eyes are used to connect the steel foot of ball and socket-shaped insulators, commonly found at the bottom of such insulators, providing support and ensuring stable connections in overhead lines.

- Transmission Line Construction: They are integral to the assembly of transmission towers where they offer a secure point of attachment for various electrical components, enhancing the overall stability and reliability of the transmission lines.

- Electrical Network Maintenance: WS Socket Eyes are used in the maintenance of electrical networks, playing a critical role in the inspection, upgrade, and repair of transmission lines.

- Diverse Weather Resistance: Given their galvanized finish, they are suitable for use in diverse weather conditions, protecting electrical connections from the elements and ensuring consistent performance.

Certificate Display

Factory Tour

Why choose us?

Professional

Professional

Fast Delivery

Fast Delivery

Good Price

Good Price

High Quality

High Quality

FAQs

Who are we?

We are Manufacturer more than 21 years experience in Binzhou City, shangdong, China. We start from 2004, sell to Domestic Market(52.00%), Eastern Asia(25.00%), Africa(10.00%), Mid East(6.00%),Southeast Asia(4.00%),South Asia(3.00%). There are total about 301-500 people in our office.

How can we guarantee quality?

What can you buy from us?

House eletric wire, Anti-aging wire, Solar PV cable, Control cable, Shielded computer cable, Low/Medium/High Voltage power cable, Aluminum alloy cable, Aerial insulated cable, Steel core aluminum standed wire, LSZH cable, Fireproof cable, Wind power cable, EV charging cable, Energy storage cable, Mining cable, etc.

Why should you buy from us not from other suppliers?

hengwang cable company has passed ISO9001 quality management system, ISO14001 environmental management system, ISO45001\German TUV certification\CE certification, the company is a finalist for the state power grid and a national”High-tech Enterprise.

What services can we provide?

Accepted Delivery Terms: FOB,CFR,EXW,FAS,DDP; Accepted Payment Currency:USD,EUR,CAD,AUD,GBP,CNY; Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,Western Union,Cash; Language Spoken:English,Chinese,Japanese,German,Russian

If I need customize Packing Cartons, is that available?

Yes, we have production line for packing box and cartons. we can make it according to your special requirement. If you are interested in our goods , please kindly send an inquiry to us !

Contact us to get your quote!

Products

Related Products

our products

NEED HELP

Contact Info

- Email: info@uni-groundrod.com

- Phone: +86 15515963170

- WeChat: +86 15515963170

- WhatsApp: +86 15515963170

- Address: No.26, Tongxiang City, Zhejiang Province,China

© Copyright 2025 by Uni Electric Group Co,Ltd. All Rights Reserved.