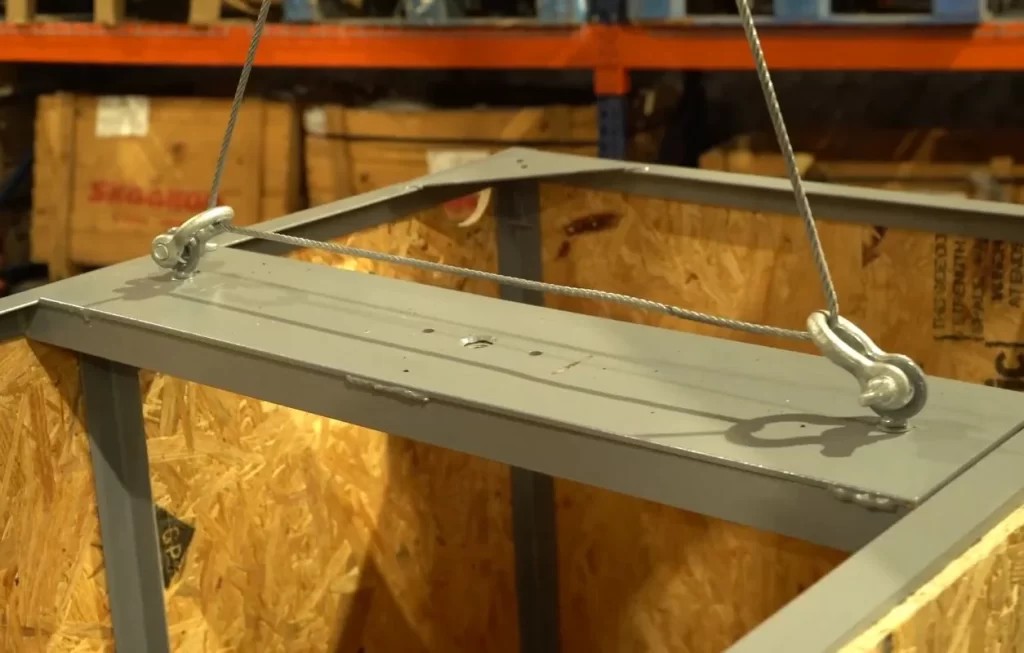

Eye Bolts

Temperature Range:

Suitable for operation in temperatures ranging from -40°C to +85°C, ensuring performance in various climatic conditions.

Humidity:

Can operate effectively in environments with high humidity, providing reliability in moist conditions.

Weather Resistance:

Designed to withstand harsh weather conditions, including high winds, heavy rain, and UV exposure.

Corrosive Environments:

The hot-dip galvanized coating or stainless steel construction provides excellent resistance to corrosion, making eye bolts suitable for environments exposed to salt, chemicals, or industrial pollutants.

Share:

Product Description

Product Overview:

Eye bolts are versatile hardware components designed for a variety of lifting, rigging, and anchoring applications. They consist of a threaded shank with a loop or eye at one end, allowing for secure attachment to various materials, including wood, steel, and concrete. Eye bolts are essential in construction, industrial, and marine settings due to their strength and reliability.

Types of Eye Bolts:

- Forged Eye Bolts:

- Forged instead of formed, these one-piece fasteners provide higher load ratings, making them suitable for heavy-duty lifting and rigging applications.

- Screw Eyes:

- These are screws with a head molded into an eye or loop, typically used for guiding cables or wires as well as for lifting and rigging.

- Shoulder Eye Bolts:

- Feature a shoulder below the eye, allowing them to be installed flush with the mounting material. This design provides additional strength and stability.

- Thimble Eye Bolts:

- Have an opening that functions as a thimble for rope or wire, reducing wear and tear on the materials.

- Pivoting Eye Bolts:

- Designed to spin 180° with a bottom that swivels 360°, allowing for greater flexibility in various applications.

Structural Features:

- Threaded Shank:

- The threaded shank allows for secure attachment to different materials, providing a reliable connection.

- High-Quality Material:

- Made from high-strength steel, stainless steel, or other durable materials to ensure long-lasting performance and resistance to corrosion.

- Variety of Shapes:

- Available in various shapes and designs, including oval, round, and thimble, to accommodate different applications.

- Load Ratings:

- Designed to meet specific load ratings, ensuring safety and reliability in lifting and rigging operations.

Installation Method:

- Preparation:

- Ensure all necessary tools and materials are available before starting the installation process. Verify the specifications of the eye bolts to ensure compatibility with the application.

- Threading:

- Thread the eye bolt into the pre-drilled hole in the material, ensuring it is properly aligned and tightened securely.

- Securing:

- Use appropriate nuts and washers if necessary to secure the eye bolt in place and ensure a firm connection.

- Inspection:

- Inspect the installation to ensure the eye bolt is securely fastened and properly oriented. Check for any signs of damage or misalignment.

Applicable Environmental Conditions:

- Temperature Range:

- Suitable for operation in temperatures ranging from -40°C to +85°C, ensuring performance in various climatic conditions.

- Humidity:

- Can operate effectively in environments with high humidity, providing reliability in moist conditions.

- Weather Resistance:

- Designed to withstand harsh weather conditions, including high winds, heavy rain, and UV exposure.

- Corrosive Environments:

- The hot-dip galvanized coating or stainless steel construction provides excellent resistance to corrosion, making eye bolts suitable for environments exposed to salt, chemicals, or industrial pollutants.

Specifications

| Type | Dia | Length(mm) |

|---|---|---|

| Eye Bolt | M16 | 250 |

| M20 | 350 | |

| Thimble eye bolt | M16 | 2400 |

| M20 | 2400 |

Product Advantages

- 1. Eye bolts are a critical component in various applications, particularly those that require secure fastening and reliable load-bearing capabilities. Here’s an expanded list of their advantages:

- 2. Outstanding Strength: Eye bolts are designed to withstand substantial loads. Their strength is a result of the robust construction and the use of high-quality materials, ensuring they can handle heavy weights without failure.

- 3. High Durability: The longevity of eye bolts is due to their resistance to wear and tear. They are made to last in tough environments and can maintain their integrity over extended periods of use.

- 4. Heat Treatment: Many eye bolts undergo a heat treatment process that enhances their mechanical properties. This process can include quenching and tempering, which harden the bolt and then relieve internal stresses, respectively, leading to improved toughness and resistance to deformation.

- 5. Quenching: This is a heat treatment technique where the eye bolt is heated and then rapidly cooled. Quenching increases the hardness of the bolt, making it more resistant to wear and capable of withstanding higher loads.

- 6. Tempering: After quenching, tempering is used to reduce brittleness and internal stresses within the eye bolt. This process involves heating the bolt to a certain temperature and then cooling it slowly, resulting in a more ductile and shock-resistant material.

- 7. Excellent Impact Handling: Eye bolts are capable of absorbing and distributing impact loads effectively. This makes them ideal for applications where sudden forces are expected, such as in lifting equipment or heavy machinery.

Application Places

Eye bolts have a wide range of applications due to their versatility and strength. Here are some common uses where eye bolts are particularly beneficial:

- Rigging and Lifting: They are commonly used in rigging and lifting operations to secure loads. The eye provides a convenient point for attaching lifting slings or chains.

- Machinery and Equipment: Eye bolts are used to secure machinery and equipment in place, ensuring they are stable and secure during operation.

- Construction: In construction, they are used to hang heavy objects, such as chandeliers, or to secure scaffolding and other temporary structures.

- Automotive: They are used in automotive applications for securing tow hooks and other heavy loads.

- Marine: In the marine industry, eye bolts are used for securing ropes and cables on boats and ships, such as for mooring lines or anchor lines.

Certificate Display

Factory Tour

Why choose us?

Professional

Professional

Fast Delivery

Fast Delivery

Good Price

Good Price

High Quality

High Quality

FAQs

Who are we?

We are Manufacturer more than 21 years experience in Binzhou City, shangdong, China. We start from 2004, sell to Domestic Market(52.00%), Eastern Asia(25.00%), Africa(10.00%), Mid East(6.00%),Southeast Asia(4.00%),South Asia(3.00%). There are total about 301-500 people in our office.

How can we guarantee quality?

What can you buy from us?

House eletric wire, Anti-aging wire, Solar PV cable, Control cable, Shielded computer cable, Low/Medium/High Voltage power cable, Aluminum alloy cable, Aerial insulated cable, Steel core aluminum standed wire, LSZH cable, Fireproof cable, Wind power cable, EV charging cable, Energy storage cable, Mining cable, etc.

Why should you buy from us not from other suppliers?

hengwang cable company has passed ISO9001 quality management system, ISO14001 environmental management system, ISO45001\German TUV certification\CE certification, the company is a finalist for the state power grid and a national”High-tech Enterprise.

What services can we provide?

Accepted Delivery Terms: FOB,CFR,EXW,FAS,DDP; Accepted Payment Currency:USD,EUR,CAD,AUD,GBP,CNY; Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,Western Union,Cash; Language Spoken:English,Chinese,Japanese,German,Russian

If I need customize Packing Cartons, is that available?

Yes, we have production line for packing box and cartons. we can make it according to your special requirement. If you are interested in our goods , please kindly send an inquiry to us !

Contact us to get your quote!

Products

Related Products

our products

NEED HELP

Contact Info

- Email: info@uni-groundrod.com

- Phone: +86 15515963170

- WeChat: +86 15515963170

- WhatsApp: +86 15515963170

- Address: No.26, Tongxiang City, Zhejiang Province,China

© Copyright 2025 by Uni Electric Group Co,Ltd. All Rights Reserved.