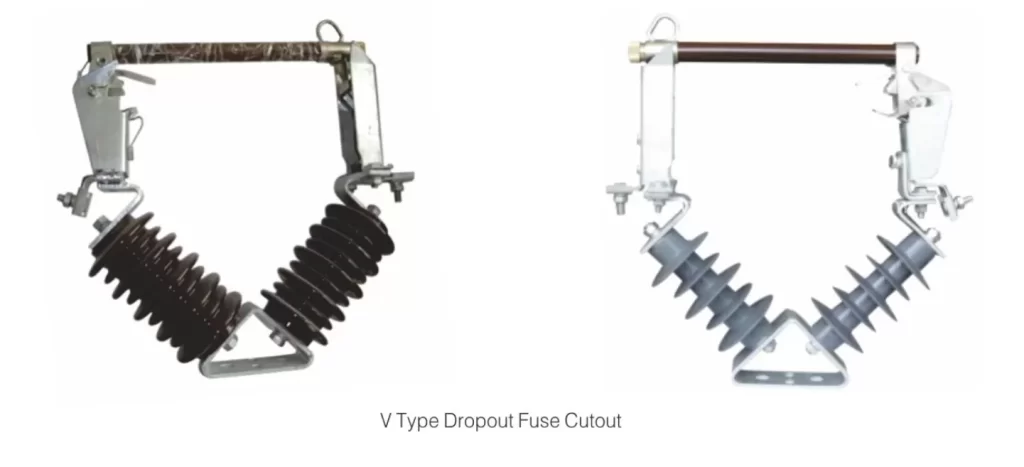

Polymer Dropout Fuse Cutout

- Standard:IEC 60282-2:2008, IEEE Std C37.41-2008, IEEE Std C37.42-2009.

- Supply Ability:50000/month

- Voltage:10-38kV

- Color:Gray or customized

Share:

Product Description

Product Description

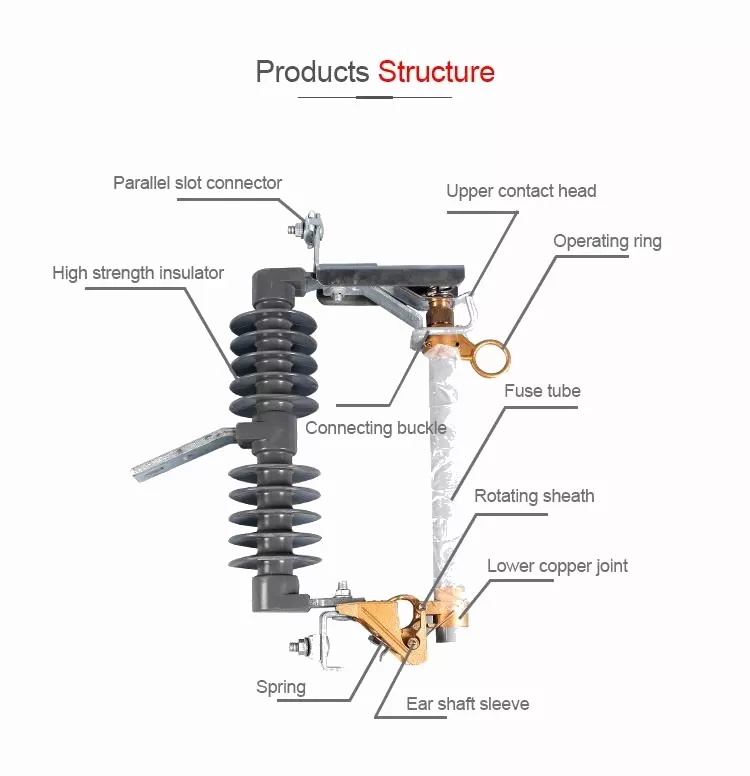

Dropout Fuse Cutout is composed of insulator supports and fuse tube,static contacts is fixed on two sides of insulator support and moving contact is installed on two ends of fuse tube.Fuse tube is composed of inside extinguishing tube,outer phenolic compound paper tube or epoxy glass tube.Load switching fuse cutout provides enforced elastic auxiliary contacts and arc-extinguishing enclosure for switching on/off loading current.At normally working via fuse link tightened the fuse tube is fixed to form up of close position.In case system occur faults,fault current result in fuse melt immediately and take place electric arc,which let arc-extinguishing tube being heated and explode a lot of gas.This will produce high pressure and blow off the arc along with tube.

After fuse link melt moving contact has no tightened strength again,mechanism is locked and fuse tube dropout.Cutout now is in open position.

When it needs to switch off during cut out loading.Operator shall via insulating operating bar pull the moving contact,at its beginning main contact and auxiliary static contact is contacted still.

Whiling pulling the auxiliary contact is separated between auxiliary contacts there occur electric arc and the arc will be lengthened in arc-extinguishing enclosure gap and meanwhile arc-extinguishing explode gas to blow off the arc during current passing zero.

Material:Silicone rubber or Porcelain.

Manufacturing Standard:IEC 60282-2.

Parallel-groove connector

Tinned for No.6 soild through 250 KC mil stranded copper or aluminum.

Recoil bar

Heavy galvanized steel(which is also used for inserts, hangers, structural bolts and nuts)

Brid proof-design insulator

Higher insulation characteristics than ANSI distribution-cutout standards and equal in most cases to ANSI switch and bus standards

Lower contacts

Not visible-silver-to-silver, provide dual current path, independent of hingepivot, Stainless-steel backup springs prevent arcing when tube rises in hinge during recoil

Upper Contacts

Silver-to-siver at both surfaces

Attachment hooks

For load buster. Heavy construction also serves to guide tube during closing

Fuse tube

Fiber-lined epoxy fiber glass

Toggle joint

Collapses to permit dropout when link severs

Sturdy ferrules

Pinned to top and bottom of tube for permanent alignment, Large, accessible lifting ring.

Trunnion pocket

Secures tube in hinge during closing

Trunnion casting

Surfaces around trunnion bear on broad hinge surfaces to keep tube in alignment during closing

Flipper

Gives high-speed terminal separation, quick cable flip-out, and(in concoction with the toggle joint) reduces transmission of forces to fuse link during closing

Specifications

Technical Details

| Type model | Rated voltage

(kV) |

Rated current

(A) |

Breaking current

(kA) |

Impulse

voltage BIL (kV) |

Power frequency

withstand voltage (kV) |

Leakage distance

(mm/kV) |

Material |

|---|---|---|---|---|---|---|---|

| HRW-11/100 | 11 | 100 | 6.3 | 100 | 35 | 25-31 | Polymer |

| HRW-11/200 | 11 | 200 | 10 | 100 | 35 | 25-31 | Polymer |

| HRW-11/400 | 11 | 400 | 12.5 | 100 | 35 | 25-31 | Polymer |

| HRW-12/100 | 12 | 100 | 6.3 | 110 | 40 | 25-31 | Polymer |

| HRW-12/200 | 12 | 200 | 10 | 110 | 40 | 25-31 | Polymer |

| HRW-15/100 | 15 | 100 | 6.3 | 125 | 45 | 25-31 | Polymer |

| HRW-15/200 | 15 | 200 | 10 | 125 | 45 | 25-31 | Polymer |

| HRW-18/100 | 18 | 100 | 6.3 | 130 | 50 | 25-31 | Polymer |

| HRW-18/200 | 18 | 200 | 10 | 130 | 50 | 25-31 | Polymer |

| HRW-21/100 | 21 | 100 | 6.3 | 140 | 58 | 25-31 | Polymer |

| HRW-21/200 | 21 | 200 | 10 | 140 | 58 | 25-31 | Polymer |

| HRW-24/100 | 24 | 100 | 6.3 | 150 | 65 | 25-31 | Polymer |

| HRW-24/200 | 24 | 200 | 10 | 150 | 65 | 25-31 | Polymer |

| HRW-27/100 | 27 | 100 | 6.3 | 160 | 68 | 25-31 | Polymer |

| HRW-27/200 | 27 | 200 | 10 | 160 | 68 | 25-31 | Polymer |

| HRW-30/100 | 30 | 100 | 6.3 | 170 | 70 | 25-31 | Polymer |

| HRW-30/200 | 30 | 200 | 10 | 170 | 70 | 25-31 | Polymer |

| HRW-33/100 | 33 | 100 | 6.3 | 175 | 75 | 25-31 | Polymer |

| HRW-33/200 | 33 | 200 | 10 | 175 | 75 | 25-31 | Polymer |

| HRW-33/400 | 33 | 400 | 12.5 | 175 | 75 | 25-31 | Polymer |

| HRW-36/100 | 36 | 100 | 6.3 | 180 | 80 | 25-31 | Polymer |

| HRW-36/200 | 36 | 200 | 10 | 180 | 80 | 25-31 | Polymer |

Product Advantages

1. Lightweight and Easy to Handle: Polymer dropout fuse cutouts are significantly lighter than their porcelain counterparts, making them easier to handle, transport, and install. This reduces labor costs and installation time.

2. High Strength and Durability: Made from high-strength polymer materials, these fuse cutouts offer excellent mechanical strength and durability.

3. Superior Weather Resistance: Polymers used in dropout fuse cutouts are highly resistant to UV radiation, moisture, and temperature extremes.

4. Improved Insulation Properties: Polymers provide excellent insulation properties, reducing the risk of electrical faults and improving the overall safety of the electrical system.

5. Hydrophobic Surface: The hydrophobic nature of polymer materials ensures that water and other contaminants do not adhere to the surface. This helps in maintaining the insulating properties and reducing the risk of flashovers and electrical faults, even in wet or polluted environments.

Application Places

Polymer Dropout Fuse Cutouts are used in various applications within the power transmission and distribution industry. Here are the main application places:

1. Overhead Distribution Lines: Polymer Dropout Fuse Cutouts are widely used in overhead power lines to protect transformers, capacitor banks, and branch lines from faults and overloads.

2. Transformers: These fuse cutouts are installed on distribution transformers to provide overcurrent protection and to isolate the transformer in case of a fault.

3. Capacitor Banks: They are used to protect capacitor banks in distribution networks by disconnecting them during fault conditions.

4. Branch Circuits: Fuse cutouts are employed on branch circuits to protect the equipment and cables from damage due to overcurrents or faults.

5. Renewable Energy Installations: They are increasingly used in renewable energy systems, such as solar and wind farms, to protect the equipment and ensure safe operation.

6. Industrial and Commercial Facilities: Polymer Dropout Fuse Cutouts are also utilized in industrial and commercial facilities for protecting various electrical equipment and ensuring reliable power supply.

These applications highlight the importance of Polymer Dropout Fuse Cutouts in maintaining the safety and reliability of electrical distribution systems.

Certificate Display

Factory Tour

Why choose us?

Professional

Professional

Fast Delivery

Fast Delivery

Good Price

Good Price

High Quality

High Quality

FAQs

Who are we?

We are Manufacturer more than 21 years experience in Binzhou City, shangdong, China. We start from 2004, sell to Domestic Market(52.00%), Eastern Asia(25.00%), Africa(10.00%), Mid East(6.00%),Southeast Asia(4.00%),South Asia(3.00%). There are total about 301-500 people in our office.

How can we guarantee quality?

What can you buy from us?

House eletric wire, Anti-aging wire, Solar PV cable, Control cable, Shielded computer cable, Low/Medium/High Voltage power cable, Aluminum alloy cable, Aerial insulated cable, Steel core aluminum standed wire, LSZH cable, Fireproof cable, Wind power cable, EV charging cable, Energy storage cable, Mining cable, etc.

Why should you buy from us not from other suppliers?

hengwang cable company has passed ISO9001 quality management system, ISO14001 environmental management system, ISO45001\German TUV certification\CE certification, the company is a finalist for the state power grid and a national”High-tech Enterprise.

What services can we provide?

Accepted Delivery Terms: FOB,CFR,EXW,FAS,DDP; Accepted Payment Currency:USD,EUR,CAD,AUD,GBP,CNY; Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,Western Union,Cash; Language Spoken:English,Chinese,Japanese,German,Russian

If I need customize Packing Cartons, is that available?

Yes, we have production line for packing box and cartons. we can make it according to your special requirement. If you are interested in our goods , please kindly send an inquiry to us !

Contact us to get your quote!

Products

Related Products

our products

NEED HELP

Contact Info

- Email: info@uni-groundrod.com

- Phone: +86 15515963170

- WeChat: +86 15515963170

- WhatsApp: +86 15515963170

- Address: No.26, Tongxiang City, Zhejiang Province,China

© Copyright 2025 by Uni Electric Group Co,Ltd. All Rights Reserved.